Benefits & advantages

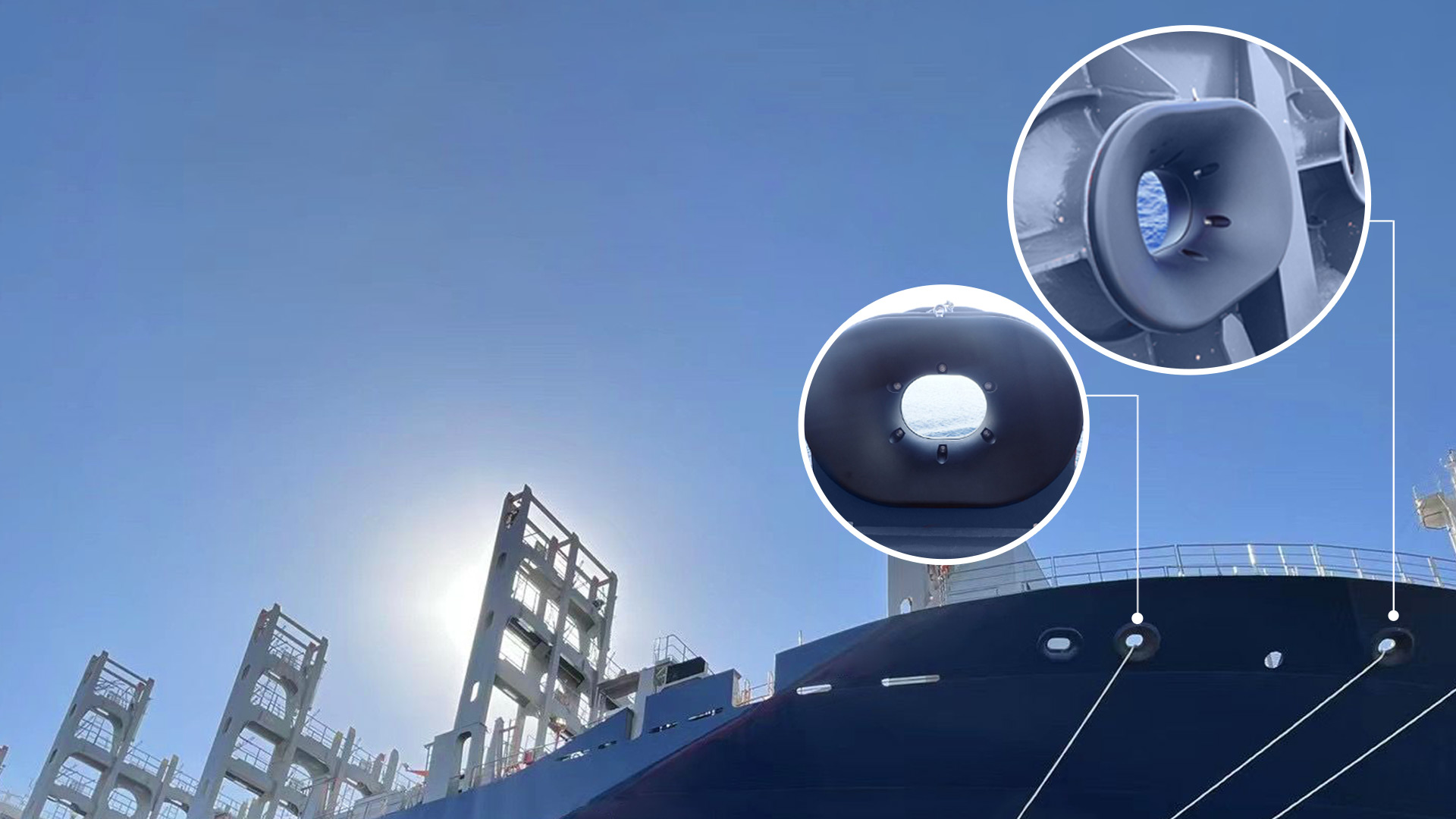

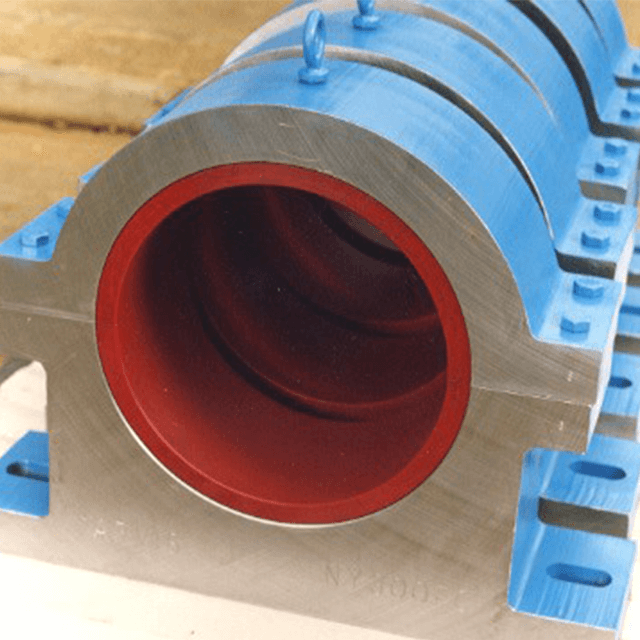

Custom manufactured from initial chemistry to end product, the patented Nylacast Chock Liner helps to deliver multiple advantages to vessels operating within key industries worldwide.

The Nylacast Chock Liner can be fitted without any hot work or dry docking, to all chock and vessel types. It can be fitted to new vessels as well as being retro fitted to existing vessels with chocks and panama fairleads.

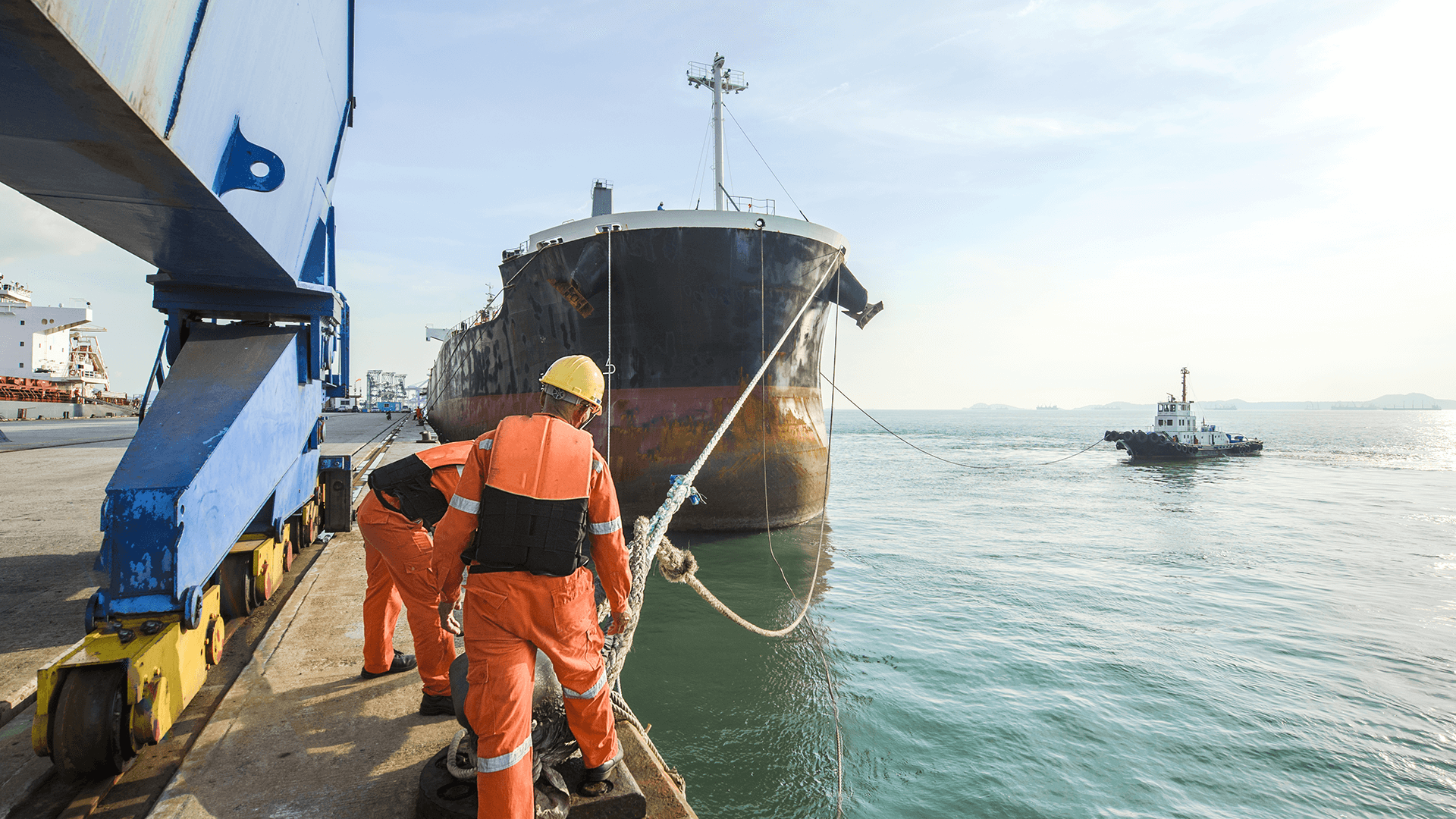

Increased Safety

Significantly reduced rope wear and abrasion eliminates risk of breaking or failure.

No need for crew to be near mooring lines under tension, as no chafe protection required.

Increased Safety

Significantly reduced rope wear and abrasion eliminates risk of breaking or failure.

No need for crew to be near mooring lines under tension, as no chafe protection required.

Reduced Rope Wear

Low friction material easily accommodates offshore mooring fibre ropes with significantly reduced risk of wear and abrasion. And eliminated need for jackets.

Reduced Rope Wear

Low friction material easily accommodates offshore mooring fibre ropes with significantly reduced risk of wear and abrasion. And eliminated need for jackets.

Maintenance Free

Self-lubricating, corrosion resistant material results in little or no maintenance needs and elimination of any painting, coating or external protection.

Maintenance Free

Self-lubricating, corrosion resistant material results in little or no maintenance needs and elimination of any painting, coating or external protection.

Easy Installation

NO hot works or dry docking needed.

Installation kit provided with delivery.

Easy Installation

NO hot works or dry docking needed.

Installation kit provided with delivery.

Corrosion Free

Corrosion resistant material protects against the arduous environments faced in the marine and shipping industry.

Corrosion Free

Corrosion resistant material protects against the arduous environments faced in the marine and shipping industry.

Load Balancing

Smooth surface finish and material provides better equalisation of mooring loads, especially when in high swell.

Load Balancing

Smooth surface finish and material provides better equalisation of mooring loads, especially when in high swell.

Technology

The Chock Liner was developed by Nylacast to optimise and enhance vessel mooring. Much of the advantages it delivers is owed to the unique and versatile materials technology developed through over 20 years of field experience in design, testing and material selection with fibre ropes. This enabled the selection of a custom formulated material which has very low friction coupled with lightweight and corrosion resistance.

Nylacast’s Chock Liner material technology accommodates HMPE rope and lowers the risk of abrasion and wear when in contact with the chock or Panama fairlead. The Chock Liner may also be used with some other polymer fibre ropes (dependent on type and construction), please liaise with Nylacast on rope choices when making an enquiry.

The unique material paired with the patented coupling technology provides vessel owners and operators with an easy installation, low maintenance product capable of increasing overall efficiency. NO hot works or dry docking is required for installation.

The Nylacast Chock Liner is also available in ATEX approved materials for specific industry requirements.

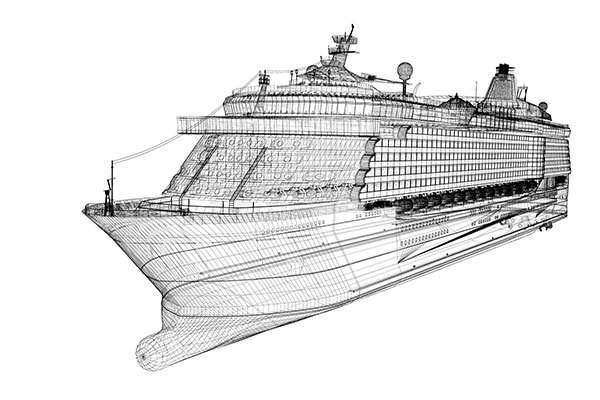

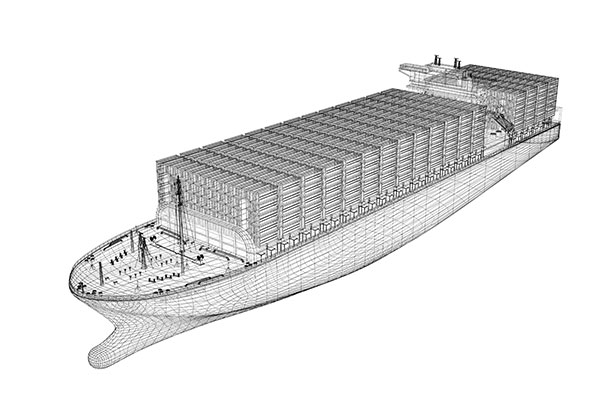

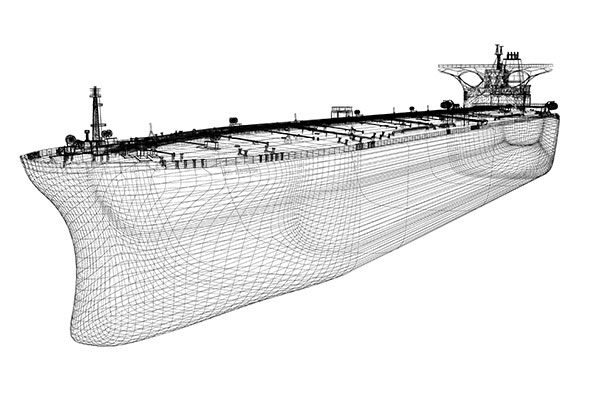

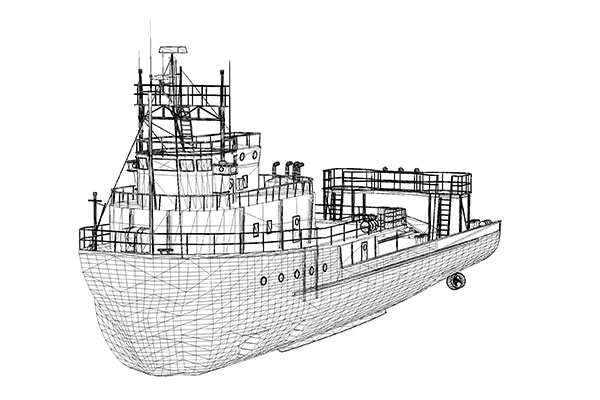

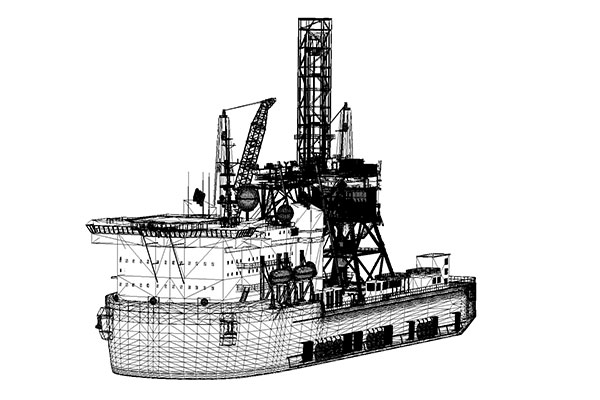

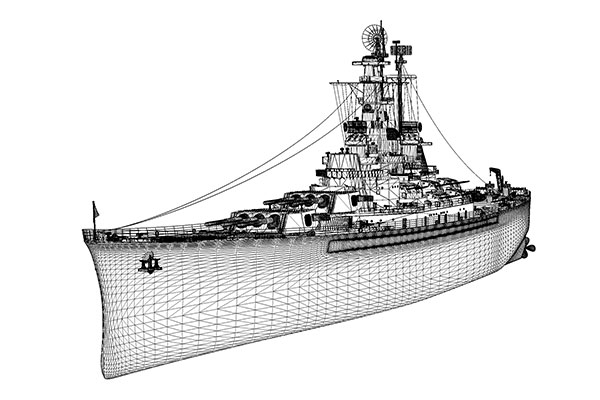

Custom created to suit specific chock size and specification, the Nylacast Chock Liner is widely used on various vessel types including:

Passenger Ships & ferries

Container Vessels

LNG Tankers & Product Carriers

Service Vessels

FPSO & Special Purpose Vessels

Navy, Yachts & Fishing Vessels

Vessels & Clients utilising Chock Liner & investing in continuous vessel safety

LNG BENUE

SHELL PRELUDE

BP BRITISH RUBY

STENA PRECISION

TECHNIP DEEP OCEAN

OTTOMAN TENACITY

VERSABAR V BUILD

PAN ASIA

RFA ARGUS

GOLAR HILLI

BP BRITISH EMERALD

BG METHANE ALISON VICTORIA

Marine products

Nylacast offer a variety of engineered products for the marine and shipping industry. The materials technology and engineering know-how results in the unique ability to provide custom manufactured, low friction, lightweight solutions for improving and enhancing marine operations.

Enquire

To discuss your vessel and projects, simply complete the form below and a member of our team will be in touch